Yachts procedures

The function of NOBELCLEAN at yachts with PU-lack

Below we explain the individual steps in the treatment of yachts:

|

|

|

|

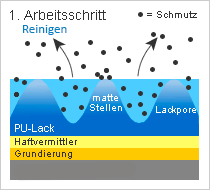

1. Work procedure

Rough cleaning without water! Removes dust and dirt deposits

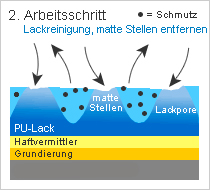

2. Work procedure

With the Nobel Flex and a special cotton plate, the varnish is gently cleansed and freed of dull areas and holograms (NC 33 + NC 35). Next, the GRP varnish, with the help of the Nobelorbit and a special Bonnet as well as with our NC31, is deeply cared a second time and prepared for the sealing. This procedure leaves a crystal clear surface (up to 95%).

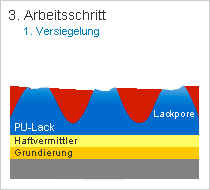

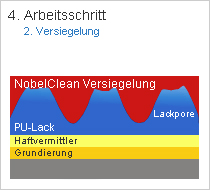

3. Work procedure

Using the Nobelorbit the lacquer surface is now compacted and filled with our special 100% layer-forming nano-sealant NC 51 plus our Diamonding glass clear coat.

The yacht now looks like new again! The aftercare is done with our NC 1. A cleaner that works without water, and is also completely organic. With NC 1, the gloss is retained. The economically sound solution for years.

Of course you can also wash your yacht with water:

NOBELCLEAN®

The function of NOBELCLEAN at yachts with GRP hull

In the following we describe the individual work procedures with the treatment of yachts, which have a GRP hull:

|

|

|

|

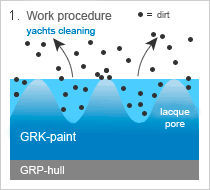

1. Work procedure

Rough cleaning without water! Removes dust and dirt deposits.

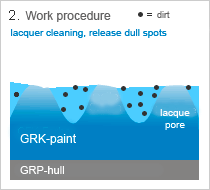

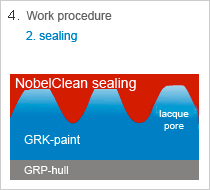

2. Work procedure

With the Nobelflex and a special cotton plate the lacquer is gently cleaned and released from dull spots and holograms (NC33 + NC 35). Next the GRP-lacqueris cleaned with the Nobelorbit and a special bonnet also with our NC 31 for a second time and prepared for the sealing. These actions lead to obtaining smooth as glass surface (up to 95%).

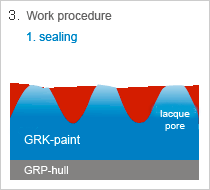

3. Work procedure

The paint is consolidated and filled now with the Nobelorbit and our special 100% layer developing acrylic sealing NC 51 plus our Diamonding glass clear coat NC 55.

The yacht looks now optically as new. For the usual cleaning you may use NC 1. A cleaner, which works without water and absolutely biological. With NC 1 the gloss remains. The economically inexpensive solution over years.

Of course you can wash your jet also with water:

NOBELCLEAN®

Services

We can polish AWLGRIPP, Dupont and all kinds of lacquer!!!!

We have named the method Diamonding clear coat treatment, not polishing. We are equally successful in retrieving the shine of fenders, removing abrasions on the sides of the hull and stern and in laying long lasting, protective sealing on the entire boat. NOBELCLEAN team has more recommendations for mega yachts than anyone in the world. We offer 10 years shine guarantee, at least - 85% gloss rate. Annually! Guaranteed!

NOBELCLEAN team does an additional refit once a year, so that to ensure the boat will always look like new. Our procedure is so profitable that our clients could save a fortune, over the years .

To make old, matt paint work look like new again, without repainting, this is the absolute strengths of NOBELCLEAN. With our patented procedure Diamonding we work without making any dirt. Completely ecologically and economically. And up to 75% more inexpensive than painting again.

A quote from Ralph Wuttke:

“The key to the typical NOBELCLEAN shine lies in the innovative method of cleaning the paint work. Without drastically diluting the paint, we are able to restore the shine of the matt areas. And it lasts for years*. The object doesn’t need to be repainted.”

*(in combination with an annual refinish)

So the service we provide is considerably more economical than repainting, and the surface can be revitalised at any time.

Another very important advantage: NOBELCLEAN team can work alongside maintenance, during any repairs. Thus there is no need to reserve additional downtime. Here we work closely together with aircraft hangars and yacht builders yards.

References

Megayacht references

| MY AL SAID | 155 M |

|

| MY RISING SUN | 143 M |

|

| M/Y KATARA | 124 M |

|

| SY EOS | 93 M |

|

| MY VIBRANT CURIOSITY | 85 M |

|

| M/Y SAPPHIRE | 73 M |

|

| MY QUEEN K | 72 M |

|

| MY SKAT | 70 M |

|

| M/Y HIGHPOWER III | 70 M |

|

| M/Y SYCARA | 68 M |

|

| MY SHUBRA II | 59 M |

|

| MY AZZURRA II | 47 M |

|

Ralf,

Further to your request for comment, I can only say that I am absolutely satisfied with the results I have experienced.

We did the first Diamonding in November 07 on F2000EX-009 HB-IGQ. The paint was almost 4 years old, the airplane allways parked outside in summer and several times de-iced in winter over these 4 years. The paint was getting dull on top of the fuselage and lacked luster. After the Diamonding, the shine was back and the rainwater streaks come off much easier.

We retreated the surface a year ago and looking at it today, I can say it still is shiny and the rainwater streaks can be removed with a dry cloth.

From the cosmetic point of view the result is absolutely satisfying.

During the checks after the diamonding in November 2007 and now, we had some spots of the paint touched up and the surface treatment did not to create a problem or requiring a special surfacing treatment before applying the paint (brush touch-up). Light sanding as usual was enough.

The pictures attached show the surface before and after the Diamonding in 2007, unfortunately the dull surface of the top of the fuselage is not very visible in the pictures, it shows up better on the wings. The leading edges were polished and treated. The shine last longer and there aren't any signs of corrosion.

Although shiny, the wing surfaces aren't more slippery than on a newly painted aircraft. Personally, I can only recommend the treatment as for the subsequent cleaning is easier and even rinsing the surface with water and a brush is enough.

In order to satisfy the newly arising requests from the Part-145 organizations for "certification", I think it would be most beneficial if Dassault Aviation could issue an No Technical Objection (NTO) statement for the procedure and the products utilized.

For any further information, please do not hesitate to call.

Best regards,

Charles Aufranc

+41 79 210 6025

Aircraft Management Services

Dear Mr. Hobiger,

I would like to introduce you to a company with which even I myself am very impressed. The company is called NOBELCLEAN and they specialize in high-tech paint gloss and long-lasting sealing

The results are impressive and I'm convinced that when selling an aircraft, the investment is certainly worthwhile. Once the surface has been treated, there really is no doubting its Prime Condition.

We had a Challenger completely treated, and were able to improve the gloss level of its old, dull paint work from approx. 65% to roughly 90% (that of a new aircraft is approx. 95%). And thanks to the special sealing process, the gloss level is also maintained in the long term.

You should have a look at their web site (nobelclean.com) and consider whether the OE-GDI shouldn't undergo this kind of treatment too. Compared to the effect, the costs for a Lear are minimal. The full treatment takes about three working days.

With kind regards from Berlin.

Robert Drover

Int. Sales Manager - Europe

Bombardier Aerospace

Pre-Owned Aircraft Sales

Tel: +49 (0) 30 8875 4687

Fax: +49 (0) 30 8875 4688

Mobil: +49 (0) 160 90566820

Dear Sirs,

after reviewing the work on the citation you did for us, we are very satisfied with the happy shining bird staying on the ramp ready for our VIPs.

We wish you and your staff many happy clients in future and thank you for the highly appreciated flexibility you demonstrated regards the performance of the work on the aircraft - great job!Best

Manfred Brunner

groWING group

aviation intelligence

Eichrueti 23a

CH-6330 Cham/Zug

Tel: +41 (0) 41 210 41 41

Fax: +41 (0) 41 210 41 42